Reject systems

Reject systems are essential components of automated quality control, ensuring that non-compliant products detected by weighing systems, metal detectors, or vision inspection systems are reliably removed from the production line. The goal is to prevent defective or contaminated products from reaching the end customer while maintaining a continuous production flow.

Process Description

Process Description

- When a defect is detected by an upstream inspection system, the reject mechanism is triggered.

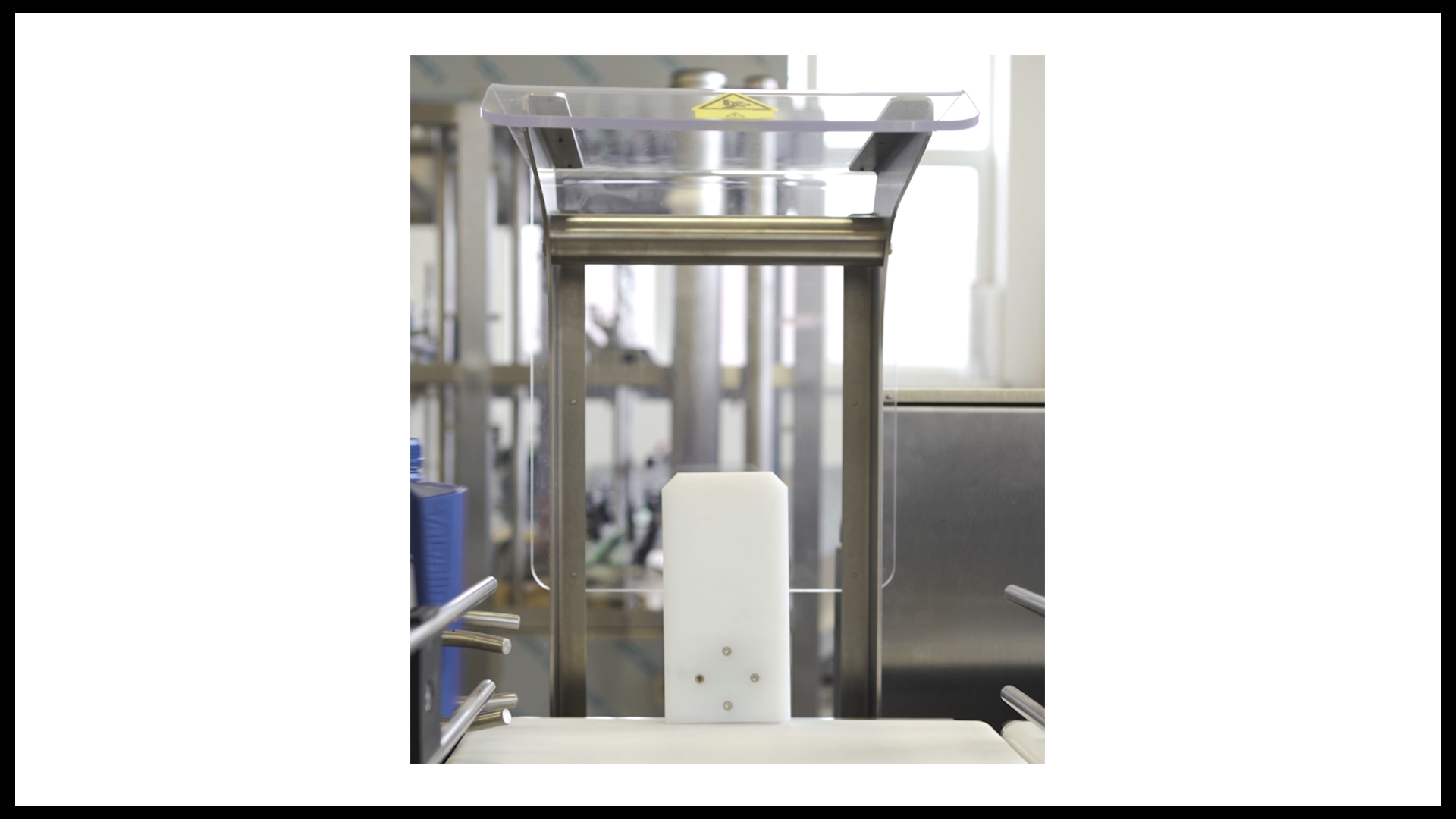

- Depending on the type and speed of the line, different rejection technologies are used – including air nozzles, pushers, flaps, drop belts, retractable conveyors, or swing arms.

- The rejected item is diverted into a dedicated reject bin, often equipped with sensors or locked containers to ensure proper disposal and traceability.

Technical Description

Technical Description

- Reject systems are selected based on product size, weight, line speed, and inspection type.

- All units are made from stainless steel or other hygienic materials suitable for food and industrial environments.

- High-speed actuators and precise timing ensure accurate rejection even at high throughput.

- The system can be equipped with bin full sensors, reject confirmation sensors, and safety interlocks for controlled operation.

- Integration with inspection systems allows for rejection data logging and real-time feedback.