AdBlue Filling Technology

31.03.2022

Demand for AdBlue products is constantly growing and so is workload for many chemistry industries and companies. We have had put together a short list of machinery that can be very helpful as well as time and personnel efficient.

Let's have a look!

POUCHLINE

Pouchline HS is the perfect solution for automatic handling, filling and closing of doypacks of different shapes and sizes.

Pouchline HS is equipped with a manipulator for automatic removal of bags from boxes or cartons. This saves time for the operator, who can then focus on other activities.

The product is dosed by rotary pumps, high dosage accuracy is ensured by Endress Hauser flow meters. The device is suitable for all types of liquid and paste products.

The basic equipment of the Pouchline HS is a closure unit for screw caps.

The finished bags then exit via a conveyor belt, so the machine can be further combined with automatic secondary packaging equipment such as automatic cartoners.

Pouchline HS is an easy to use machine that saves time and operator labour while providing high precision and quality packaging for your products.

FILLING OF CANISTERS

Canisters are often used for packaging products such as AdBlue, windshield fluid or engine oil. Albertina offers a complete solution for canister filling and subsequent handling.

Our equipment can offer automatic loading of containers into the filling line, high-precision filling, capping with different types of caps, label application, group packing or cartoning and subsequent palletizing.

When using special materials, filling lines for flammable or aggressive products are possible.

Albertina's filling lines are tailor-made for each project and thus meet all expected requirements.

PALLET FILLER

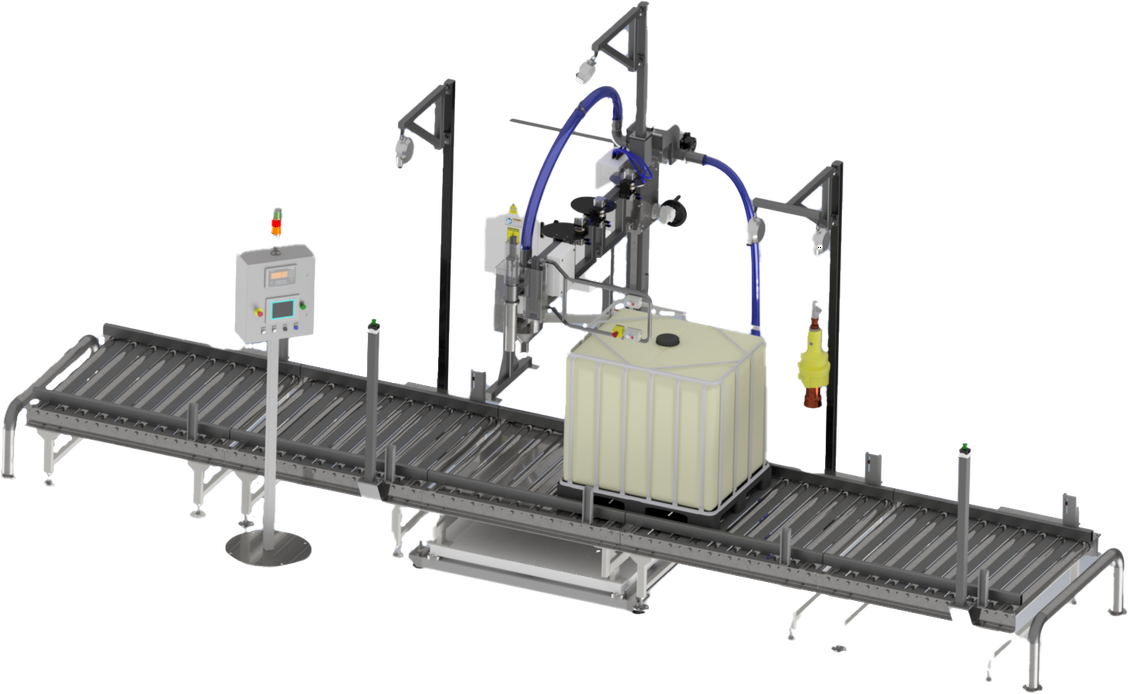

IBC & DRUM BULK FILLER is a machine designed for filling of large barrels and IBCs.The pallet with drums is placed under position of filling nozzle or on the infeed roller conveyor by a forklift - in case of version with conveyor is pallet automatically transferred to the filling position.

The operator guides the filling nozzle over the drum or IBC opening and press the button to fix the arm in the position.

The operator then presses the second button to start the filling process. The nozzle dives into the container, the valve opens and the filling starts. When the pre-set weight is nearly reached, the valve and nozzle partially close, and when the value is reached, the nozzle fully closes.

Then the pallet moves to the next station where the containers are closed.